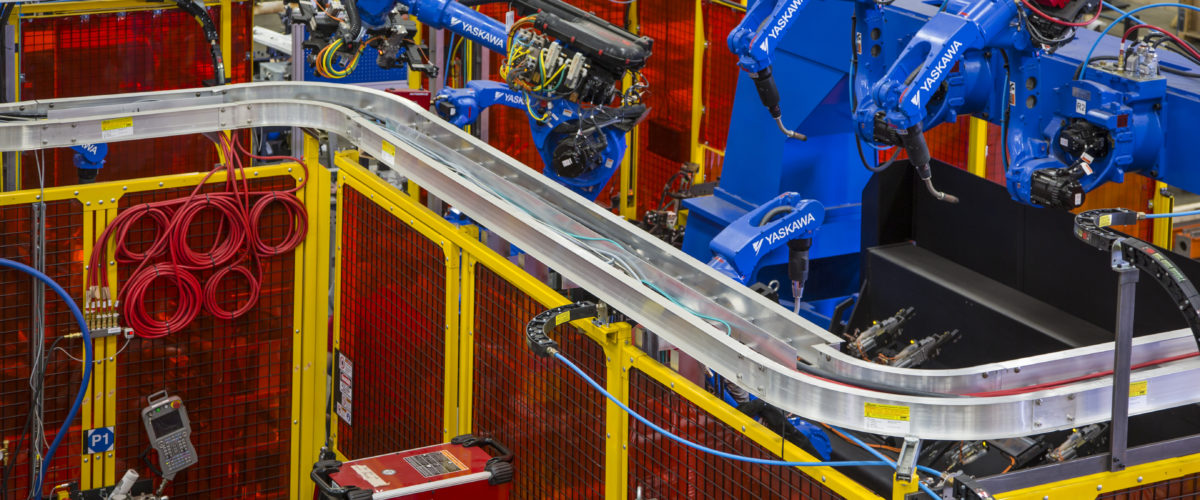

Robotic Weld and Thermal Systems

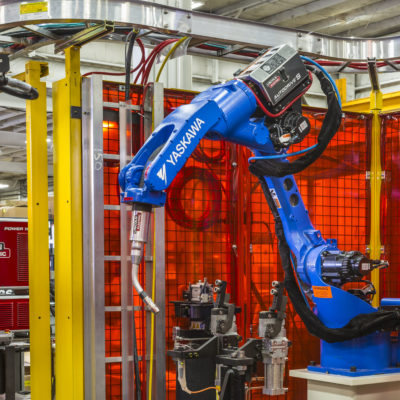

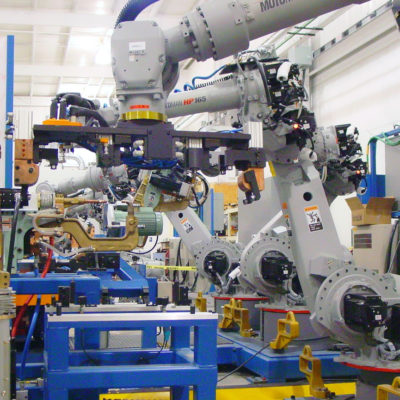

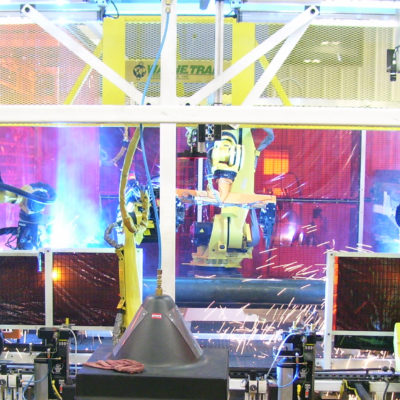

Our robotic systems excel at welding and cutting, quickly and accurately while reducing safety risks to your personnel. Using the industry’s most advanced cutting and welding technologies, seamlessly integrated to work with rugged, state-of-the-art robots, our robotic engineers study your process, then equip you to deliver products that meet the highest quality requirements while optimizing cycle times.

Cutting and joining metal are ideal operations for robotic solutions. Wayne Trail’s custom robotic welding and thermal systems eliminate the variability and risk typically associated with this aspect of metal fabrication, boosting productivity and ensuring quality. The controls for this type of equipment can be highly complex, but our integrated, turnkey control systems are simple to use, which makes troubleshooting the equipment fast and easy.

Our specialized robotics engineers also have years of hands-on welding and technical experience and are familiar with domestic and international electrical and mechanical components. Whether you are building a new system or retrofitting an existing one, we can work within the requirements of your specifications. Our team integrates Tennessee Rand™ premier tooling to further increase uptime and to meet dimensionally critical specifications.