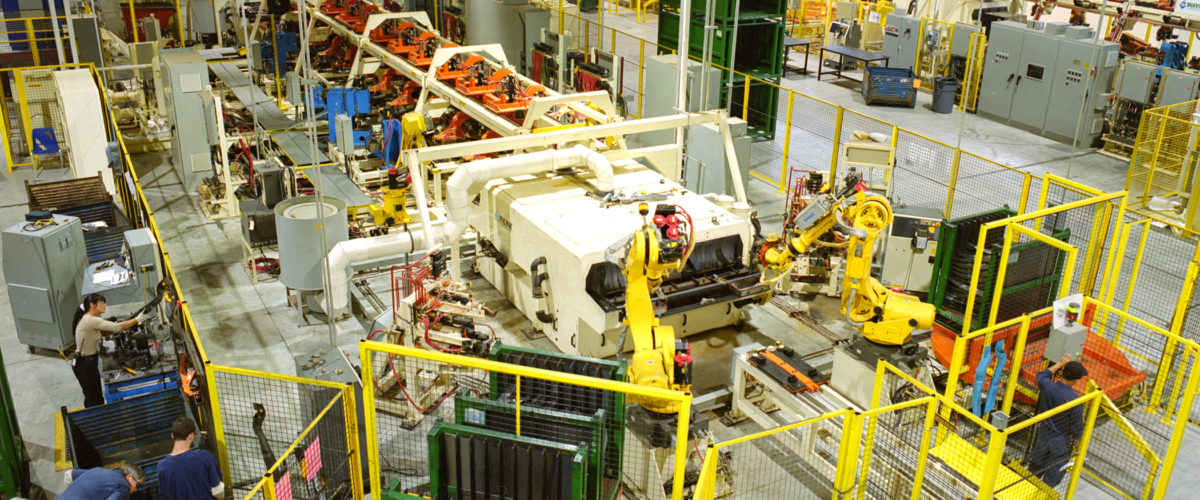

Hydro‐Form/Structural Frame Automation

Now a mainstay of automotive manufacturing, hydro-forming technology provides engineers with exceptional flexibility in designing high-performance automotive components. By using highly pressurized fluid and special dies to form metal, hydro-forming enables the production of complex shapes and stronger, lighter and stiffer unibody parts. Although used primarily by the auto industry for making products from sheet and tube, this technology is finding additional applications almost daily.

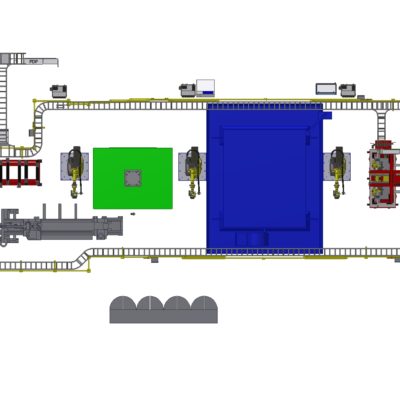

In addition to the actual hydro-forming, producing hydro-formed tubular components effectively and economically requires manufacturing support systems before and after the hydro-forming process itself. We provide the automation and support systems that act in concert with the main hydro-forming equipment to ensure consistent, accurate and fast performance. These complementary systems include:

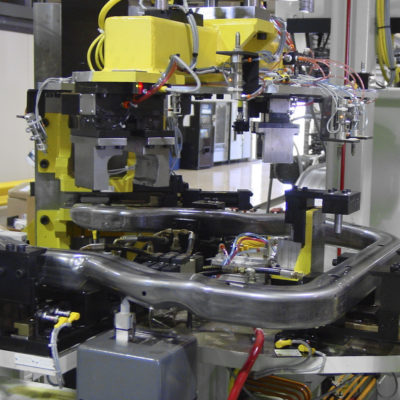

- Pre hydro-form workstations and automation products

- Post hydro-form processing cells

- Unload, transfer and racking systems

- Control and system integration