FLEX LASE® PRO Scanner-Based Laser Processing Cell

The Flex Lase® Pro features a high-speed, 3-axis scanner and an exceptionally large field of view and working area. This arrangement is excellent for prototyping, process development and production. It also works in other applications requiring extreme processing speed and high accuracy. End users can specify a wide range of options to suit job-specific requirements.

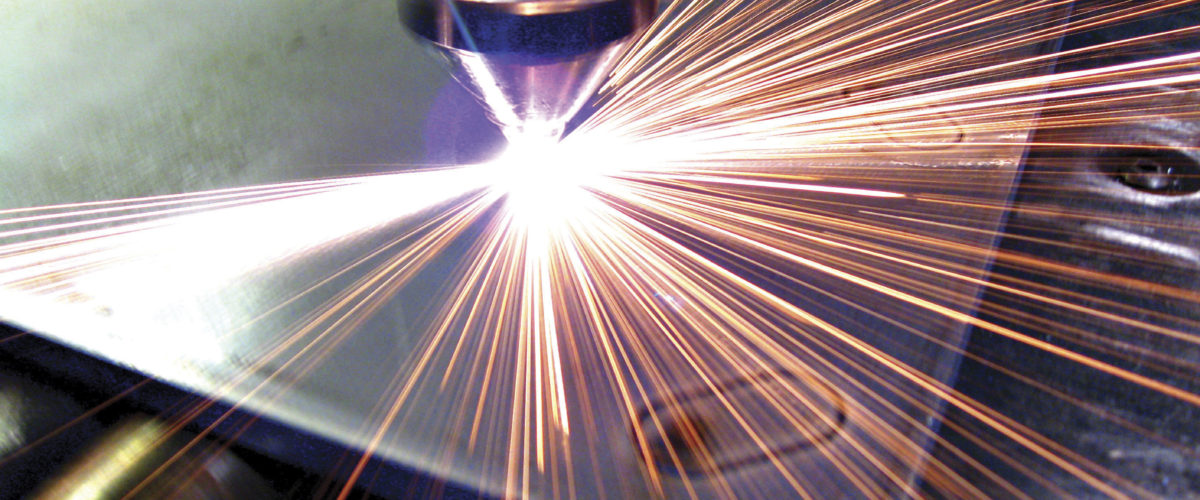

Designed for safe, efficient use in every environment from lab research and prototype development to limited production or high-speed manufacturing operations, Flex Lase® Pro can be used for laser cutting, welding, marking, heat treating, sealing, bonding, ablation, character scribing, engraving and additive manufacturing – working in materials ranging from metals (bare or coated) and exotic alloys, to polymers, plastics, stone and glass. Flex Lase® Pro can handle a variety of applications in automotive, aerospace, semi-conductor, medical and general industry, and is particularly well suited for processing a variety of components needed within green technology market segments.

A wide range of options can be specified by the end user to further enhance the configuration of Flex Lase® Pro. Laser type and power (single or multi-mode), scanner type, scanner FOV (field of view), focused spot size, process monitoring and other options can be selected to suit you project-specific requirements. Our applications team can work with you to develop a system design that meets your individual needs.