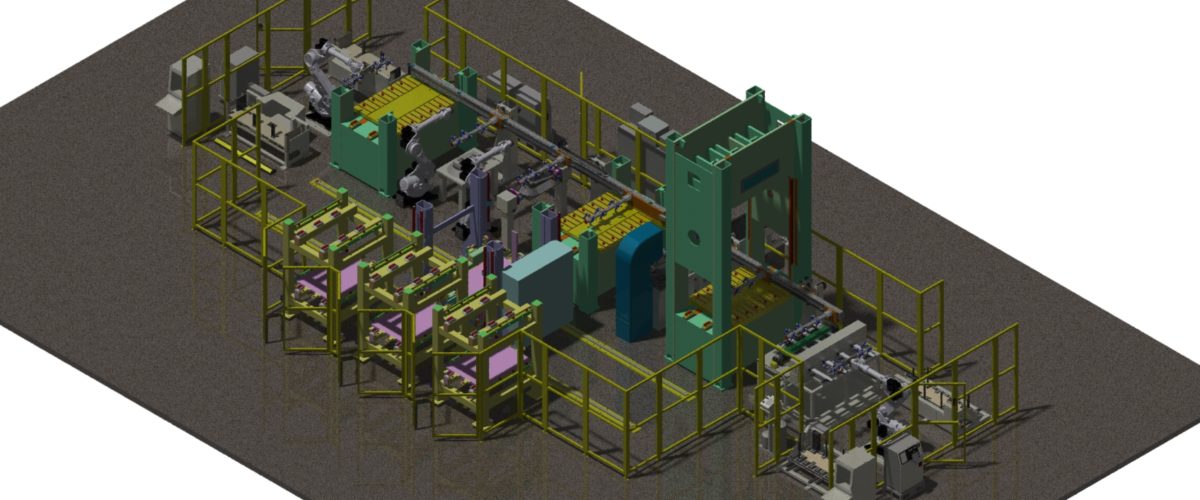

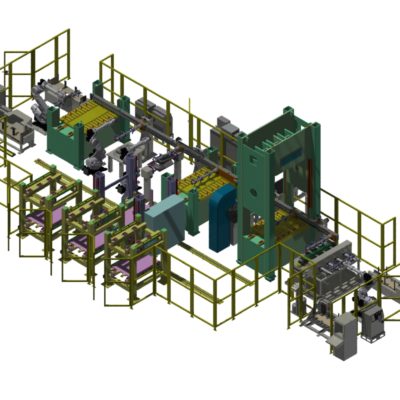

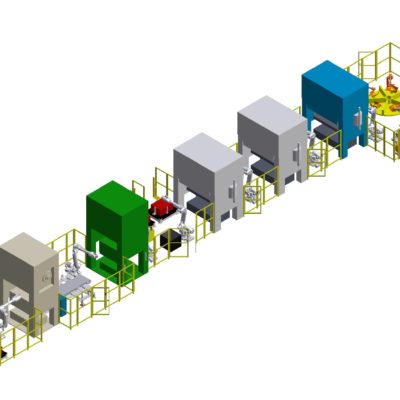

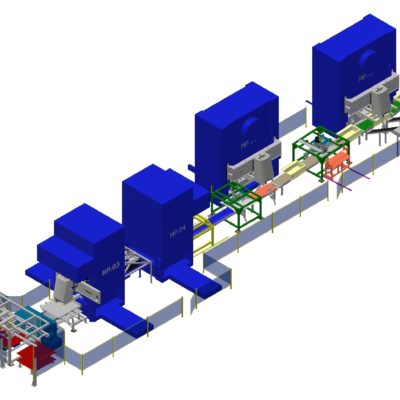

Press-to-Press Automation

Efficiency is a must when multiple presses work together. Our effective, affordable, modular automation systems for nearly any press line – new, upgraded or existing – install without any modification to footprint or foundations. Our easy-to-install systems provide centralized control and quick changeover to give you higher throughput, better quality and a safer, more ergonomically friendly operation.

It’s easy to automate a multiple-press stamping or forming line. Wayne Trail’s modular, flexible press-to-press system has a standard WTTBD servo module design. This addresses a wide range of applications and offers simplified mounting for nearly any press arrangement, whether existing, upgraded or brand new. These features keep costs down and speed up installation.

Completed Wayne Trail press-to-press systems provide higher through-put, better quality and safer handling, taking user ergonomics into account. Features on a typical system can include:

- Modular conveyors for “between-press” part handling

- Reorientation centering and handling modules

- Blank destacking system with multiple load stations

- Double blank detection

- Blank eject/reject capability

- Centralized control with user-friendly intuitive touchscreens